Your Custom Text Here

Cotty Fay Marine Design is excited to announce the addition of Computational Fluid Dynamics (CFD) to our tool box. We can offer very competitive pricing for external hydrodynamics including resistance estimates using multiphase dynamic mesh with RANS turbulence models. The package is OpenFoam and templates have been developed to accelerate the modeling and development of the domain and boundary conditions. The modeling for running resistance estimates can be developed and run very quickly. The computer time is 24-36 hours per speed point depending on speed. The hull model can include spray rails, tunnels and chine details which the designer may want to investigate.

The second level of complexity would be to add the appendages to determine their drag and wake. An optimization could be run or a range of parametric designs. The superstructure and pilothouse can be added to investigate flow and forces due to wind forces. The appendages would be modeled on a full hull using an LTS solver (Local Time Stepping).

Cotty Fay Marine Design is excited to announce the addition of Computational Fluid Dynamics (CFD) to our tool box. We can offer very competitive pricing for external hydrodynamics including resistance estimates using multiphase dynamic mesh with RANS turbulence models. The package is OpenFoam and templates have been developed to accelerate the modeling and development of the domain and boundary conditions. The modeling for running resistance estimates can be developed and run very quickly. The computer time is 24-36 hours per speed point depending on speed. The hull model can include spray rails, tunnels and chine details which the designer may want to investigate.

The second level of complexity would be to add the appendages to determine their drag and wake. An optimization could be run or a range of parametric designs. The superstructure and pilothouse can be added to investigate flow and forces due to wind forces. The appendages would be modeled on a full hull using an LTS solver (Local Time Stepping).

42M Yacht Support vessel at 11.5 knots showing running wake elevation in meters.

110M Double Ended Ferry

110M Ferry at 16.5 knots streamlines over hull and rudder.

Stepped Hull at 50k

49 ft Interceptor Hull at 50 knots wake elevation

4M Diameter Propeller

Highly loaded propeller during acceleration. The propeller is 4M in diameter producing 1298 kN with a torque of 795 kN-M.

Propeller Velocity Profile

Propeller Wash Velocity during acceleration

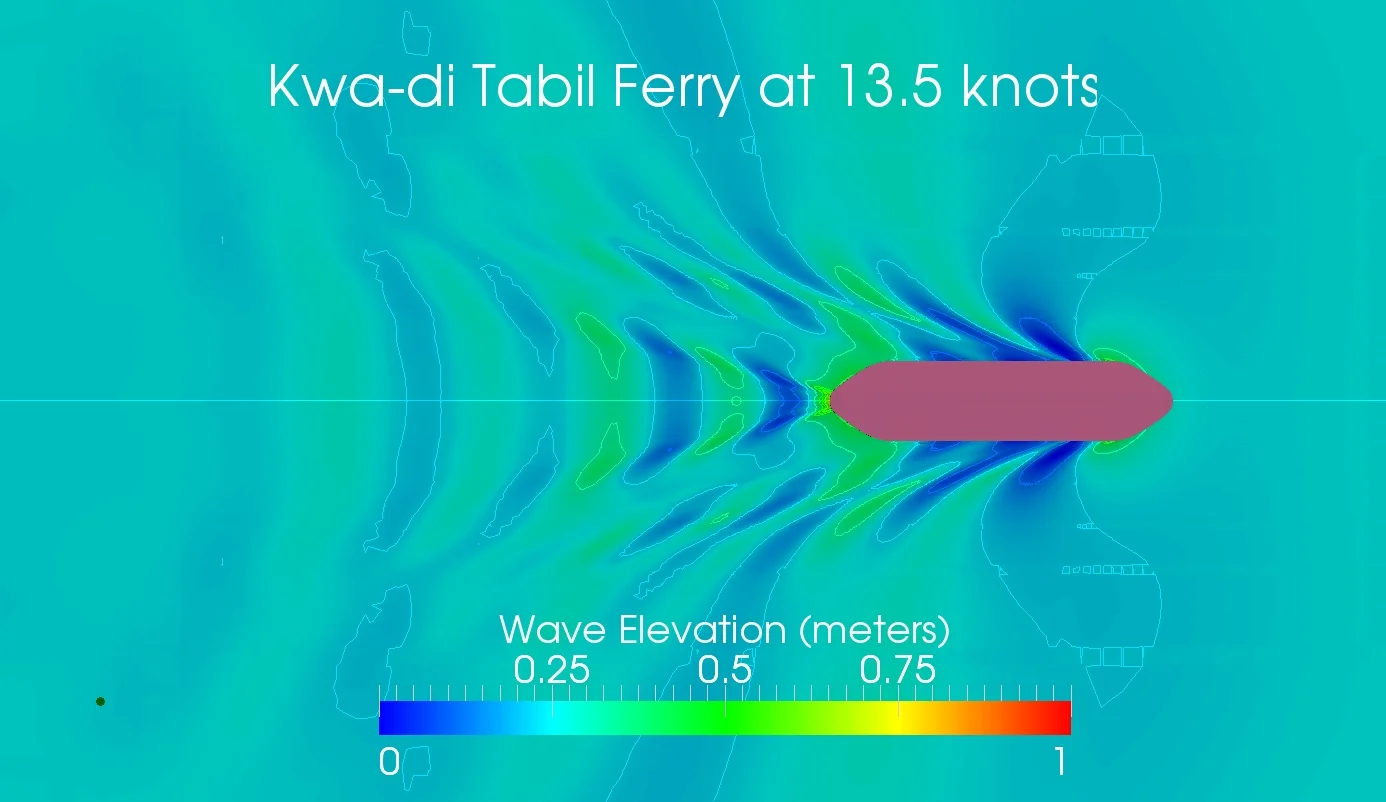

83M Ferry Wave Profile

Wave Elevation with bilge keels

Streamlines over Bilge Keel

Flow over bilge keel at 13.5 knots